As a key tool for CNC machine tools, domestic cutting tools are gradually replacing imports. The Atometrics FM-9000 Image dimension measuring instrument helps blade manufacturers to quickly measure in batches, ensuring full-size detection of each blade with an accuracy of up to 0.4 microns.

As a key cutting tool for CNC machine tools, blades are widely used in modern manufacturing fields such as automobiles, aerospace, energy, rail transportation, and mold manufacturing.

Although the field of high-end customized cutting tools is still dominated by European, American, Japanese and Korean manufacturers, with the increasing improvement of domestic cutting tool technology, domestic cutting tools are gradually replacing imports. In recent years, domestic cutting tools have accounted for more than 70% of the Chinese market and have also shown strong competitiveness in the international market.

Atometrics focuses on the production pain points of blade manufacturers and helps blade manufacturers solve various measurement problems. Today, Dr. Atometrics will first talk to you about one of the difficulties in blade manufacturing: rapid blade size measurement.

1. The key to blade manufacturing process

The manufacturing process of the blade seems simple, but there is a lot of knowledge in it. It is necessary to ensure accurate size, good wear resistance, heat resistance, durability and other characteristics.

· Powder mixing: Tungsten carbide provides hardness, while cobalt provides toughness. Alloying elements provide strength, wear resistance and heat resistance.

· Powder pressing: The powder mixture is pressed in a die to obtain a knife blank of basic shape and size.

· Sintering: Sintering is carried out at thousands of degrees Celsius to make the powder mixture particles bond together to form a cemented carbide.

· Grinding: Diamond grinding is used to make the blade meet the designed geometric size requirements.

· Edge treatment: The R angle of the cutting contact surface is precisely processed and the surface coating is increased.

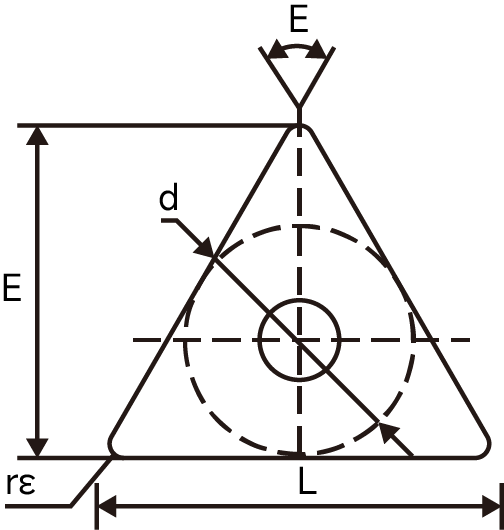

2. Geometric dimensions of the blade

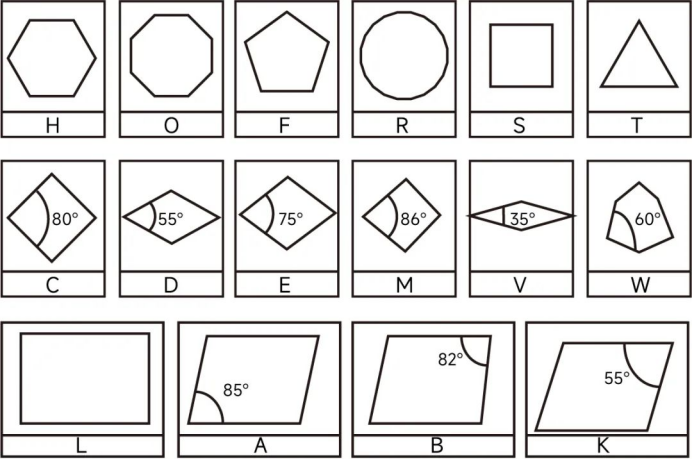

The shape and size of the blade directly determine the cutting purpose, cutting rigidity, cutting depth, cutting speed and feed rate. In order to meet different processing requirements, the blade is often designed in different shapes, and even special shapes are customized in some special fields.

3. Measurement advantages of FM-9000 one-key dimension measuring instrument

Cutting tools are generally inspected during the production process to prevent waste from flowing into the next process and wasting materials.

Cutting tools must be fully inspected before shipment. Exceeding the size will cause serious customer complaints and huge economic losses.

If you rely on manual labor and traditional measuring equipment, you cannot complete such a large number of measurement tasks. At this time, you need to use the Image dimension measuring instrument FM-9000.

Atometrics FM-9000 series Image dimension measuring instrument:

Assist major blade manufacturers to easily complete daily measurement tasks.

Only 3 steps are needed to ensure 100% size inspection of each blade, with test reports and certificates.

Step 1

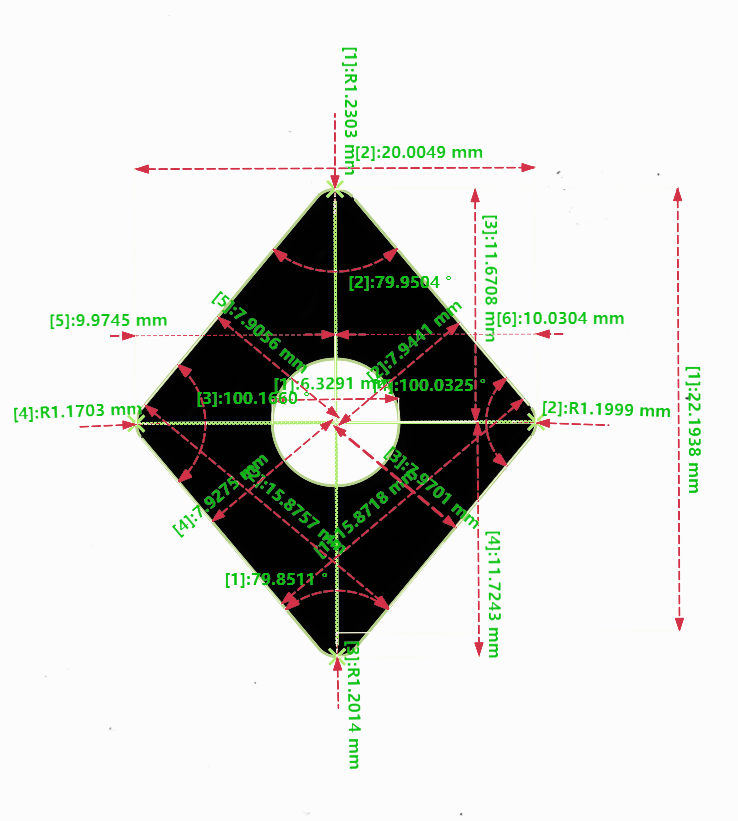

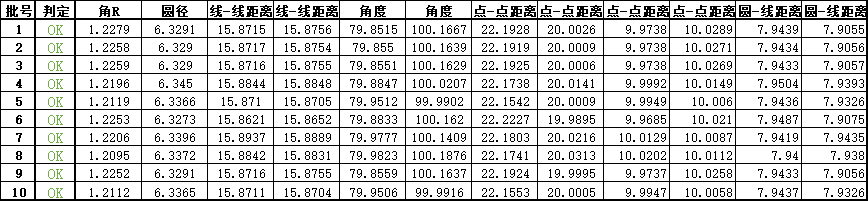

Enter the required blade measurement items according to the drawing requirements

(Easy to use, guided programming)

Step 2

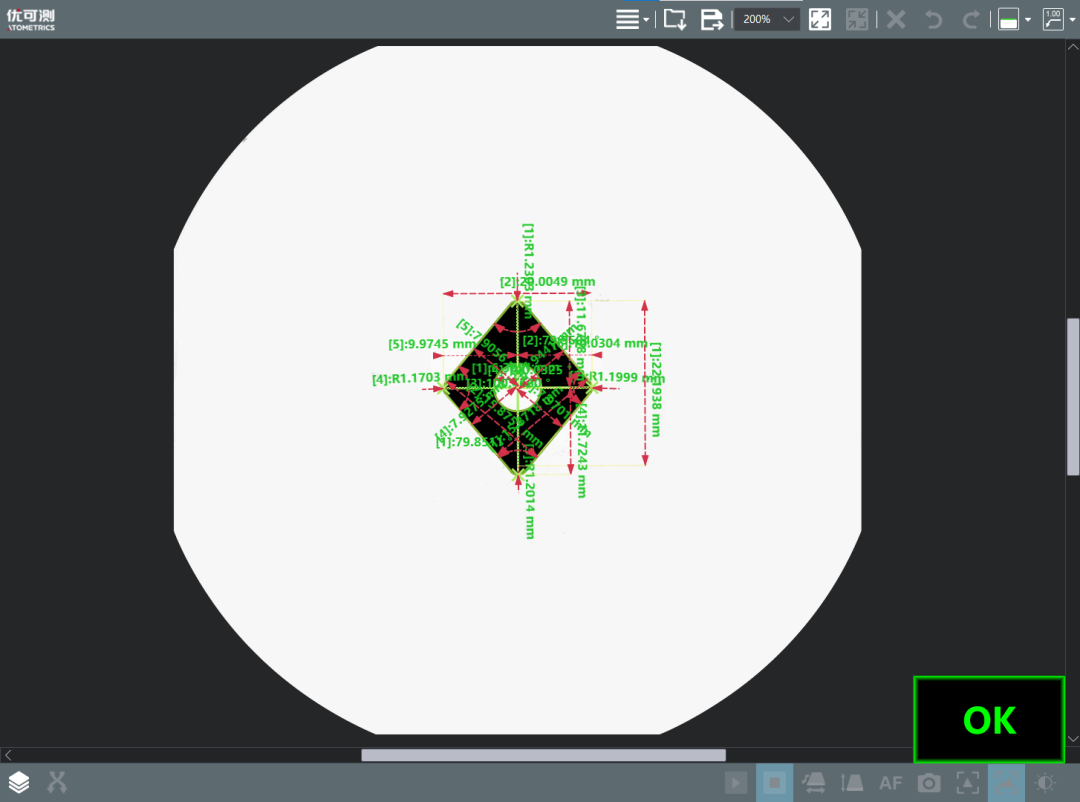

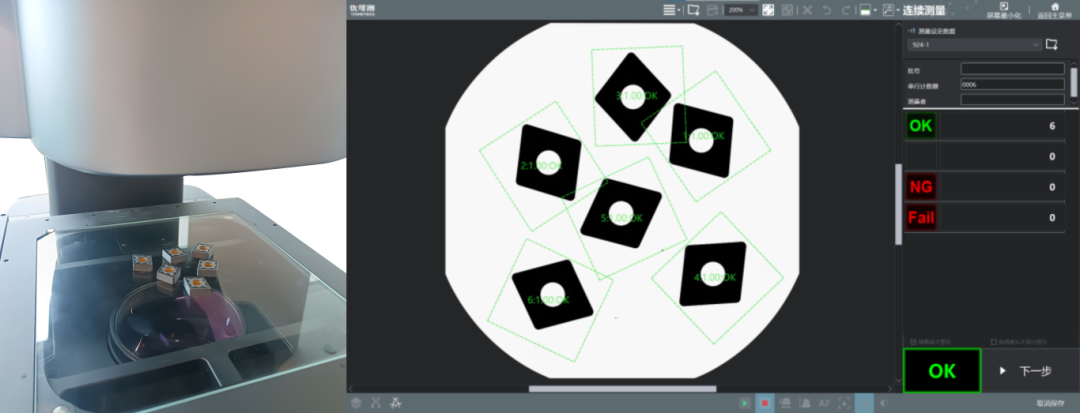

Place the blades as you like and press a button in 1 second to complete all dimension measurements

(up to 300 dimensions)

Step 3

One-click export of measurement results table

Of course, you can also measure the size of batches of blades, and just place them anywhere and the measurement can be completed instantly with one click.

In addition, FM-9000 also has the following performance advantages:

Atometrics Image Dimension Measuring Instrument FM-9000 Series

Help blade manufacturers to quickly measure the dimensions of a batch

Welcome all major blade manufacturers to inquire!