How to deal with various accuracy concepts when evaluating measuring instruments/sensors | Popular Science

In industrial measurement, accuracy is a complex concept involving multiple aspects, and is usually used to describe the accuracy and reliability of measurement results.

When choosing measuring instruments/sensors, facing the numerous accuracy names, are you worried about what they specifically describe and whether they are directly related to the evaluation requirements?

Next, Dr. Atometrics will use several popular science articles to introduce the relevant accuracy concepts of Atometrics instruments and sensors in detail.

Today's topic is:

"Common concepts related to the accuracy of measuring instruments/sensors"

Common measuring instrument/sensor accuracy includes: accuracy, precision, resolution, repeatability, reproducibility, stability, linearity, positioning accuracy and repeatability.

Accuracy is the closeness of a measurement to a true or reference value.

An accurate measurement means that it has a small deviation, that is, the difference between the measured value and the actual value is small. Accuracy is affected by systematic errors, which may arise from the calibration of the equipment, environmental factors or measurement methods.

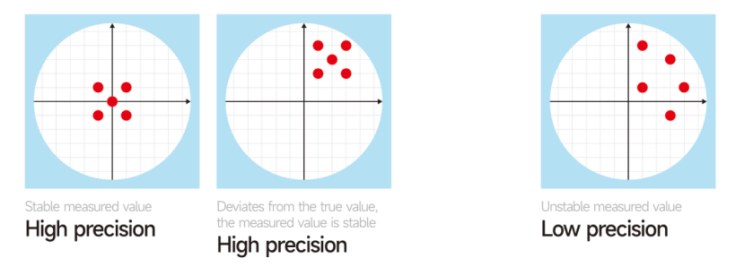

Precision describes how consistent or spread out the results of repeated measurements are.

Even if all measurements deviate from the true value, as long as they differ only slightly from each other, the measurements are considered to have high precision.

Precision

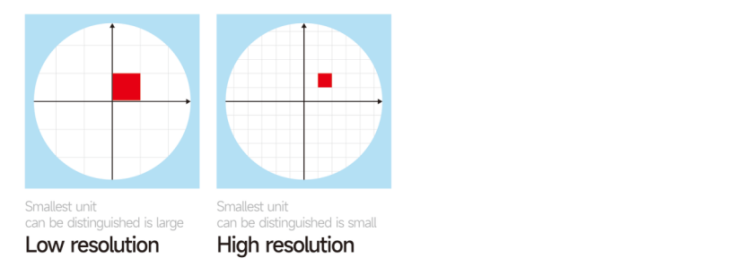

Resolution refers to the ability of an instrument to distinguish or detect the smallest size or unit of measurement.

It is an important indicator of measurement accuracy and affects the accuracy and reliability of measurement results.

Resolution

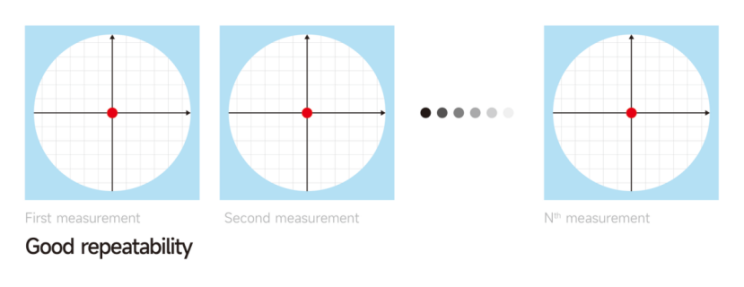

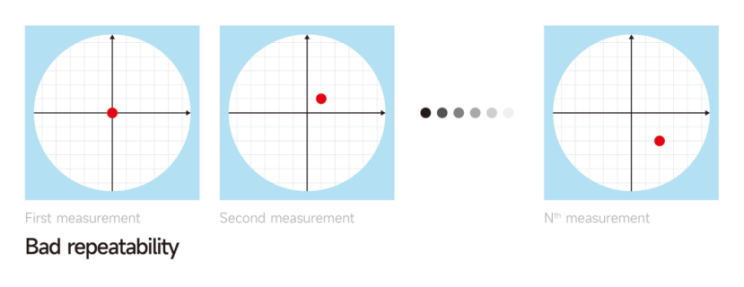

Repeatability is the ability to obtain similar results when the same measurement is repeated under the same conditions.

It focuses on the variability of measurements made under the same conditions.

Good Repeatability

Bad repeatability

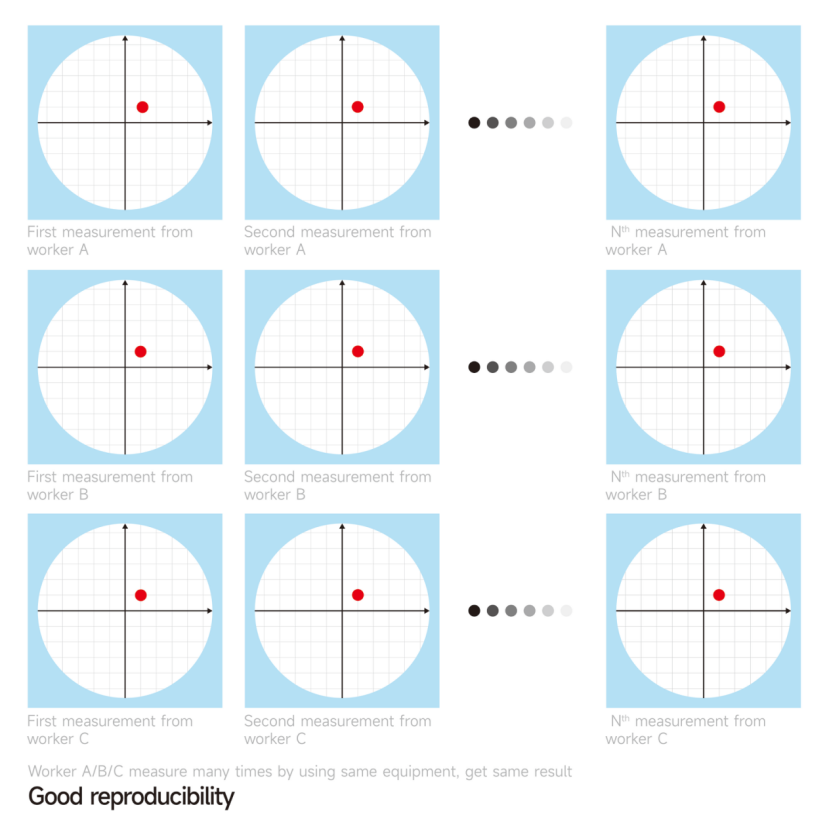

Reproducibility refers to the consistency of results when measurements are repeated under different conditions (e.g., different times, operators, same measurement system).

Good Reproducibility

Bad reproducibility

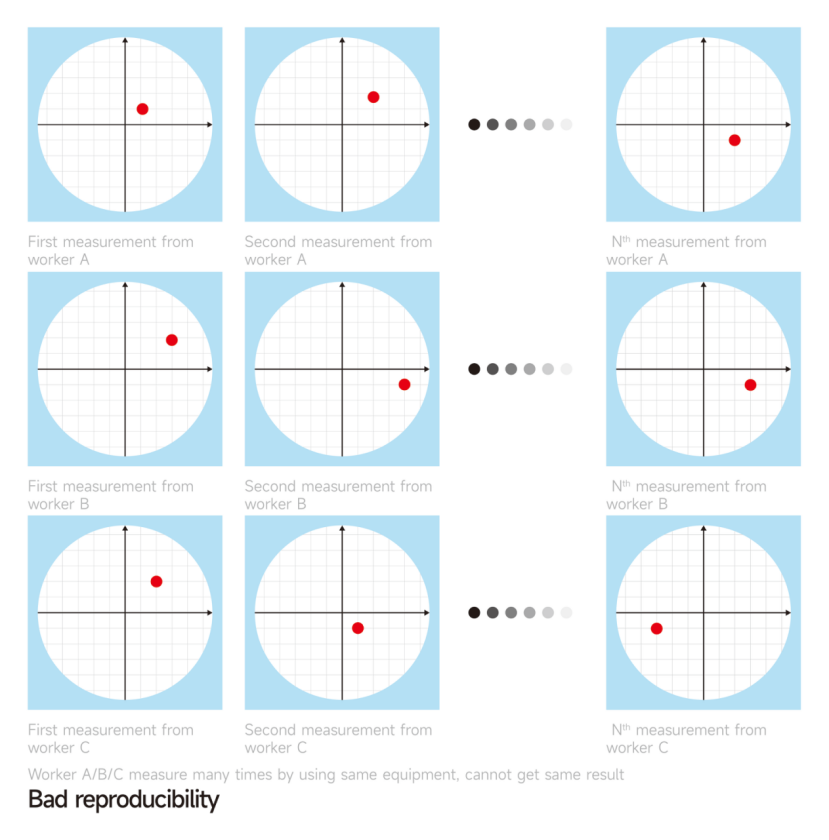

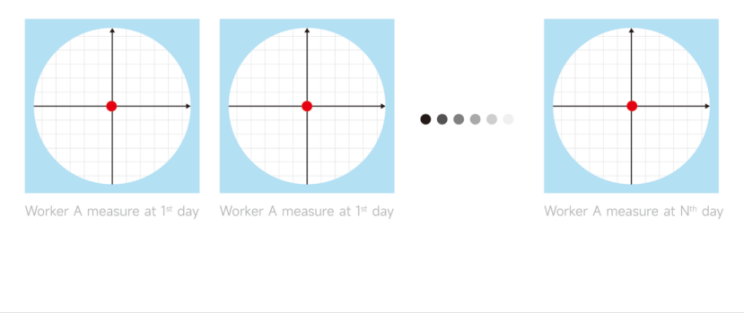

Stability is the ability of a measurement system to maintain its performance over a period of time.

Equipment can age over time, affecting measurement results.

Good stability

Bad Stability

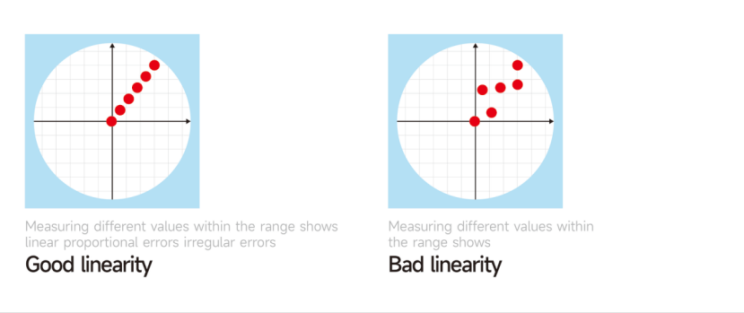

Linearity refers to the degree to which the relationship between the output and input of a measurement system is linear over the entire operating range.

Nonlinearity can result in different proportional errors at different measurement points.

Linearity

Positioning accuracy: The difference between the actual position and the expected position of the device. It is a measure of whether the device can accurately reach the specified position. It is "positioning accuracy".

Repeat positioning accuracy: The consistency of position deviation when the device reaches the same specified position multiple times under the same conditions. It reflects the stability and reliability of the device when repeatedly performing the same task. It is "positioning stability".

Positioning Accuracy and Repeat positioning accuracy

Thanks for your reading! Subscribe us to get more metrology knowledge and application cases!

Atometrics